The Go-To Shop In the West for

Steel Beam Bending Services

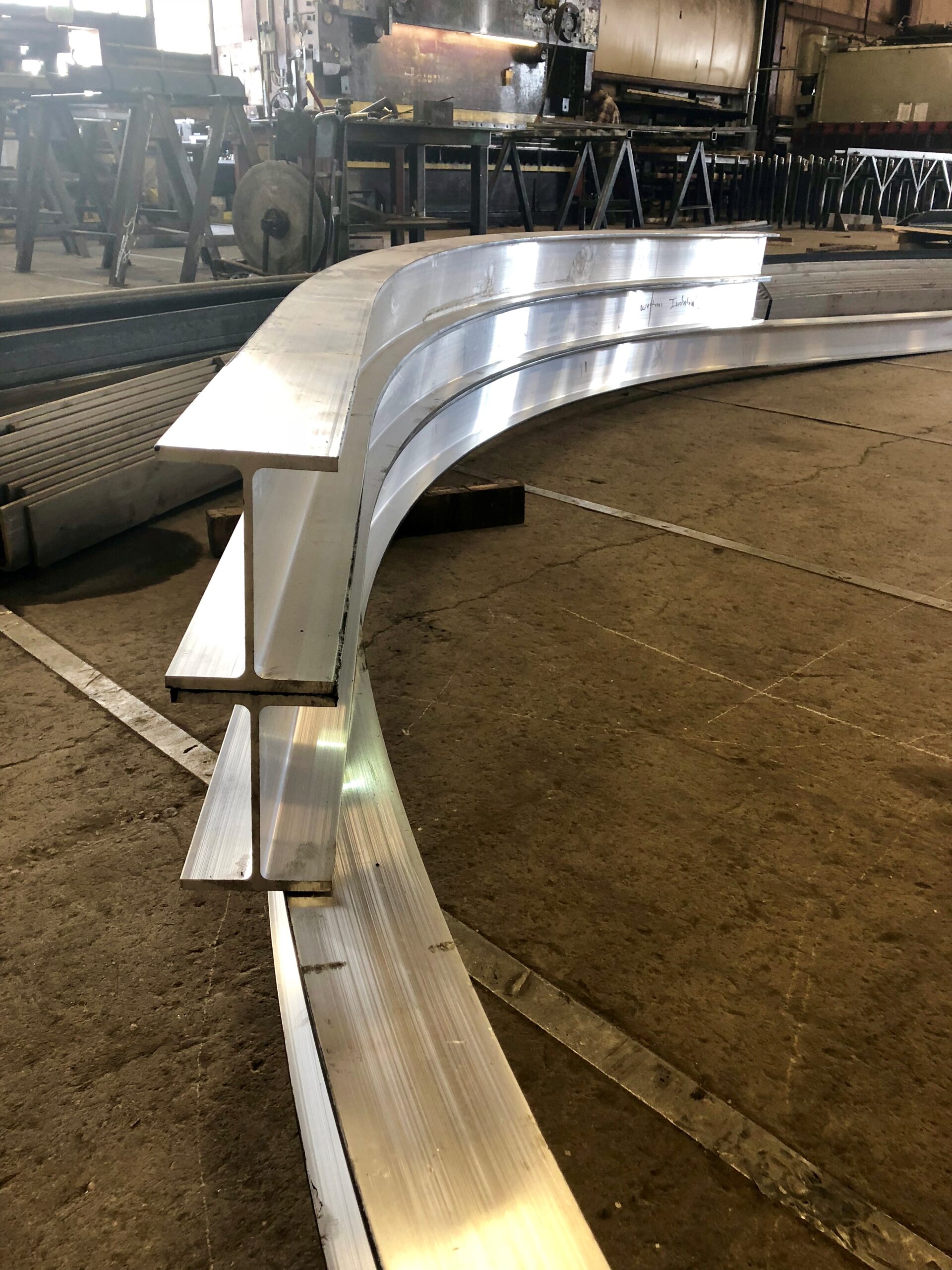

We bend the gamut of steel beam types

Because we have several machines to choose from when running your order, we make sure that we choose the machine best fit for your job to reduce your cost and minimize tangent/trim at the ends. (When beams are run through any bending machine there is a straight tangent on both ends of unrolled material that must be trimmed off before the final application. This tangent equates to the length of the rolls as when the steel is fed through it cannot start curving immediately until it’s past the roll diameter on either side).

Typically, when bending beams, the heavier the weight of the beam the nicer the end product will be. Depending on radius and beam size, there can be distortion or shrinkage expected from the bending process. With our expertise in bending, we’re able to let you know what to expect and make suggestions for the best bent beam possible.

We also have other steel forming services and a full service welding plant in-house for any additional services you may need.

Metal Beam Rolling Capabilities:

Longero can roll beams either the easy way (EW) or hard way (HW). We can roll beams as small as I-beam sizes of 3” deep, up to beams as large as W21x111# the hard way, W27x94# the hard way, and any beam sizes in between. Please contact us for a quick quote on your specific project’s beam size.

At Longero we’re able to bend the gamut of steel beam types including;

- W-Beams (straight flange)

- I-Beams/Junior Beams (tapered flanges for strength)

- S-Beams (sloped inner flange, “American Standard” beams)

- H-Beams (longer flanges)

Full-service steel fabrication

Our full-service steel fabrication plant located in Denver, Colorado offers a variety of services.